Chalwa Rotating Machine

Our solutions are fully customized to the size and capabilities of our clients.

In addition to the necessary mechanical and electrical calculations, we also conduct economic feasibility studies to ensure the optimal return on investment.

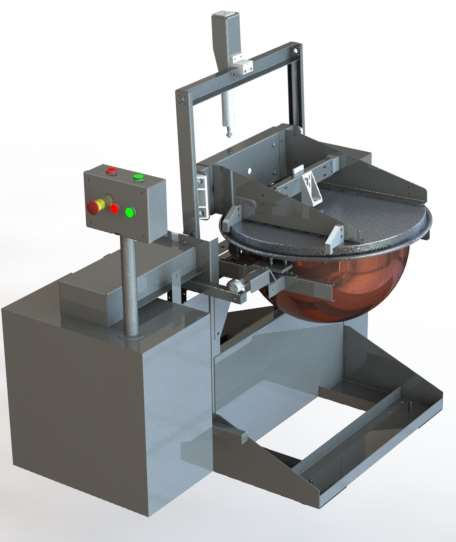

For one of the oldest halva producers, we designed and built a unique and innovative machine for overturning the baked mixture directly onto the tray. The process of overturning halva is extremely difficult and laborious, requiring the lifting of a 13 kilogram baked halva mixture with a pot weighing 5 kilograms that has just been removed from the fire.

The machine we developed completely changes this process. The baker removes the pot and places it in the machine. Then, they place the tray over the pot, and with the press of a button, allowing control at every stage, the pot is overturned in less than 2 seconds, leaving the halva ready for sale on the tray.

This innovative machine not only makes halva production independent of specialized personnel but also eliminates a sequence of non-ergonomic movements that can lead to injuries, allowing the artisan to focus on maintaining the halva recipe for many years with minimal maintenance.

Production Line Turntable

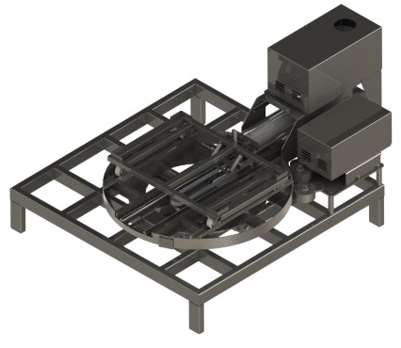

Our philosophy is that knowledge should be disseminated and reciprocated through collaborations, with the food processing and production sector being one of the industries where we seek to design and manufacture machinery for machine and production line manufacturers, aiming not to transfer knowledge among competitors but to bring them into contact. Addressing the problems that arise during the design of our production lines leads us to create unique solutions.

For example, for the issue of changing the direction of a 1- ton, 2-meter-high cart, we designed a rotary table with 3 degrees of freedom. This machine is equipped with a specially designed gripper to pick up the object from one production line, place it in the center, eliminating centrifugal forces for subsequent rotation. Then, it rotates with controlled acceleration and speed, maintaining the balance of the cart, and finally advances the object to the next production line without adding additional time to it. The machine is designed to meet all the specifications of the food industry, operating reliably with minimal maintenance costs.

Cutting Machine

We innovate by applying our acquired knowledge to different industries. Inspired by the principle of operation of the embroidery machine and applying our expertise in the design of high-performance and precision machinery, we adapted the cam follower function of the embroidery machine to a food cutting machine. We modified the motion of the cutting blade with a detachment mechanism and integrated measurement and slip avoidance mechanisms for the cutting piece. We incorporated our client’s existing products for weighing, transfer, and rejection of unacceptable cuts, and designed a complete machine ready for production.

Our deliverables, beyond the mechanical calculations, include a complete kinematic analysis, nonlinear finite element analysis for the strength of cutting tools and pre-tensioning operation, timing and operation study for PLC code generation, assembly instructions, and construction drawings.

Cart Rotation Machine

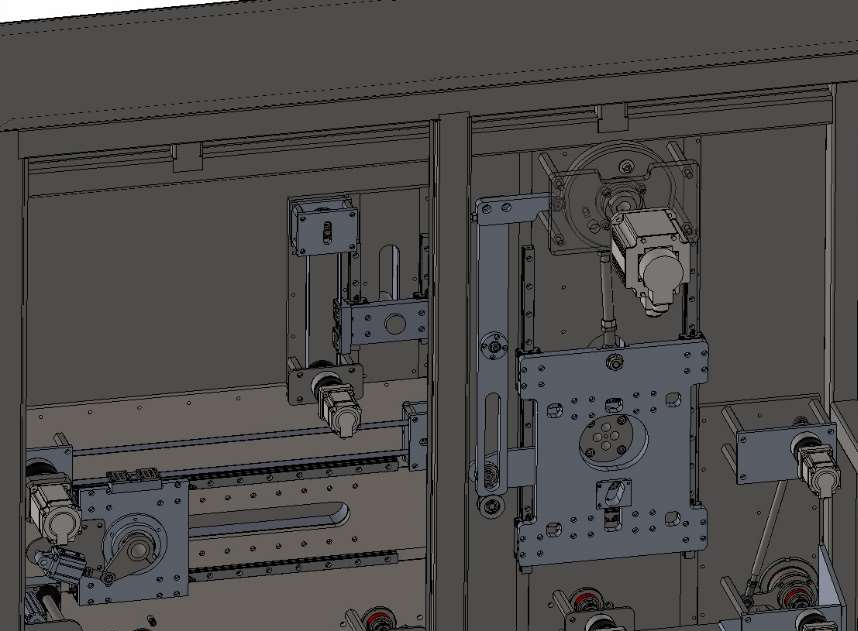

Inspired by the operating principle of hydraulic lifts and applying our expertise in designing pneumatic systems for rotating tables and high- performance, precision machinery, we adapted the lifting function to a cart tipping machine for the food industry. We employed two oppositely moving L-shaped frames for lifting and holding, applying the operating principles of CNC rotary axes to rotate a 1-ton weight with absolute precision.

Applying our knowledge of mechanical piece engagement, we brought our piece into the mechanism without the intervention of a third party and returned it to the production line. We customized the machine to fit our client’s products and designed a complete machine ready for production.

Our deliverables, in addition to mechanical calculations and piston dimensioning, include a complete kinematic analysis, finite element study for the strength of machine components, assembly and maintenance instructions, and a comprehensive folder of construction drawings.