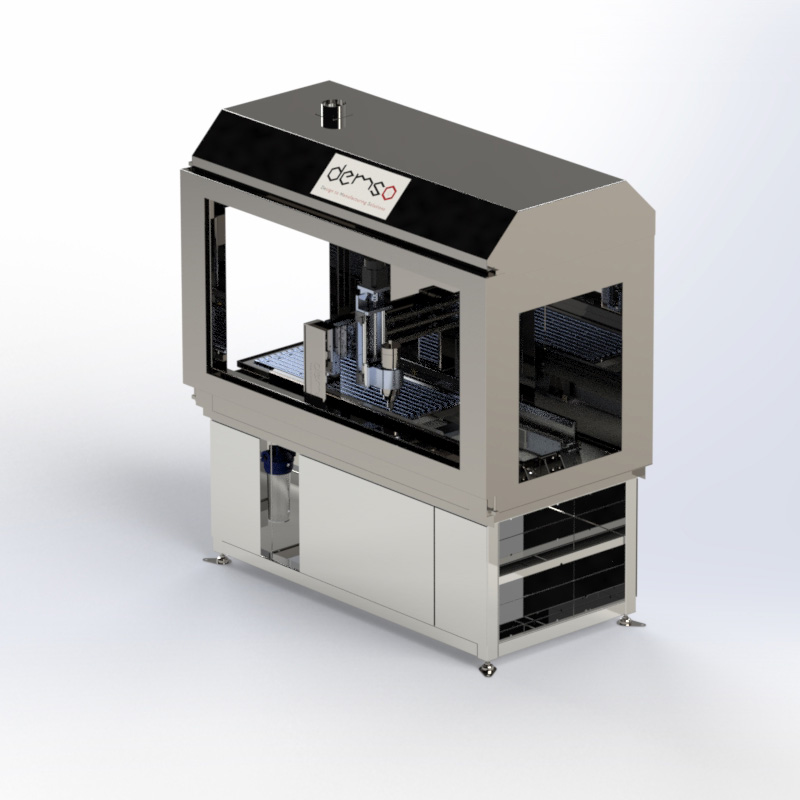

DHK CNC Series Routers

DEMSO DHK Series is an excellent choice for light to heavy-duty applications.

Robust frame constructed by milled aluminum bars is strategically reinforced with steel to withstand extreme forces when milling solid materials like aluminum and steel

Offers low-vibration machining for consistent surfaces and accuracy

High accuracy linear rails and low backlash ball screws combined with powerful closed-loop stepper motors result in high speeds up to 20m/min with enough torque to execute milling tasks on soft materials

The high-frequency 1.5 KW VFD driven spindle motor can deliver 24,000 rpm to run fast and accurate engraving even in tough materials like stainless steel yet can produce enough torque at lower speeds for milling operations on 6 and 7 series aluminum with an 8mm flat milling tool.

DEMSO DHK Series is a compact yet powerful machine that can even be placed on a rigid workbench or be purchased with an industrial ventilated enclosure to remove cooling mist from the atmosphere.

Every DEMSO DHK Router comes with a series of standard accessories, including High accuracy Hiwin sliders, Closed-loop stepper motors 12Nm, 8Nm and 5 Nm, Resolution 3um or 0.003mm, Maximum travel speed 20m/min, 1.5 kW 24,000 rpm spindle VFD Driven, 4th Axis ready, and a Single-Phase power supply.

DEMSO DHK series routers can be optionally equipped to meet your needs, with 3kW 24,000rpm spindle, 3KW 24,000rpm ATC spindle, 1.5-3KW ATC Servo spindle, Flood or Mist coolant system with recirculation or Air operated mist system, 20-40lt coolant tank with the recirculation system, Industrial enclosure with an opening for long workpieces machining, Tool measuring system, Wireless Pendant, Industrial Panel PC, 3PH power supply, and more.

Standard

equipment

- Heavy-duty milled aluminum

Frame - High accuracy Hiwin sliders

- Low backlash ball screws

- Closed-loop stepper motors: 12Nm, 8Nm, and 5 Nm

- Resolution 3um or 0.003mm

- Repeatability 9um or 0.009mm

- Maximum travel speed 20m/min

- 1.5 kW 24,000 rpm spindle VFD driven

- 4th Axis ready

- Single Phase power supply

- 3 kW 24,000rpm spindle also available

- 3KW 24,000rpm ATC spindle available

- 1.5-3KW ATC Servo spindle

- Flood or Mist coolant system with recirculation or Air operated mist system

- 20-40 lt coolant tank with recirculation system

- Industrial enclosure with opening for long workpieces machining

- Tool measuring system

- Wireless Pendant

- Industrial Panel PC

- 3PH power supply

Optional

equipment

Technical Specifications

DHK 803010

- X-Axis Travel: 830

- Y-Axis Travel: 300

- Z-Axis Travel: 200

- Clearance Z (upper edge machine frame under edge bridge): 100

- Clamping Area X: 900

- Clamping Area Y: 300

- Weight (kg): 135

- Length Overall X: 1620

- Width Overall Y: 960

- Height Overall Z: 790

- Linear Guides Diameter X/Y Ø: 20

- Linear Guides Diameter Z Ø: 20

- Additional Linear Guides X-Axis / HIWIN: HG15

- Steps per Revolution 1/8 Micro-Step: 3um

- Max Spindle RPM: 24.000

- Programmable Resolution: 3um

- Backlash: <10um

- Repeatable Accuracy: 10um

- Max. Rapid Speed X + Y: 20m/min

- Max. Cutting Speed: Depended on Material

- Digital CNC Controller 4 Axis: 4th Axis Support

- Operating System with Software for Windows / Linux: √

- Supported CAM: Solidworks CAM, 2L PRO Engraving Software

DHK 803030

- X-Axis Travel: 830

- Y-Axis Travel: 300

- Z-Axis Travel: 400

- Clearance Z (upper edge machine frame under edge bridge): 300

- Clamping Area X: 900

- Clamping Area Y: 300

- Weight (kg): 198

- Length Overall X: 1620

- Width Overall Y: 960

- Height Overall Z: 990

- Linear Guides Diameter X/Y Ø: 20

- Linear Guides Diameter Z Ø: 20

- Additional Linear Guides X-Axis / HIWIN: HG15

- Steps per Revolution 1/8 Micro-Step: 3um

- Max Spindle RPM: 24.000

- Programmable Resolution: 3um

- Backlash: <10um

- Repeatable Accuracy: 10um

- Max. Rapid Speed X + Y: 20m/min

- Max. Cutting Speed: Depended on Material

- Digital CNC Controller 4 Axis: 4th Axis Support

- Operating System with Software for Windows / Linux: √

- Supported CAM: Solidworks CAM, 2L PRO Engraving Software

DHK 803050

- X-Axis Travel: 830

- Y-Axis Travel: 300

- Z-Axis Travel: 600

- Clearance Z (upper edge machine frame under edge bridge): 500

- Clamping Area X: 900

- Clamping Area Y: 300

- Weight (kg): 225

- Length Overall X: 1620

- Width Overall Y: 960

- Height Overall Z: 1190

- Linear Guides Diameter X/Y Ø: 20

- Linear Guides Diameter Z Ø: 20

- Additional Linear Guides X-Axis / HIWIN: HG15

- Steps per Revolution 1/8 Micro-Step: 3um

- Max Spindle RPM: 24.000

- Programmable Resolution: 3um

- Backlash: <10um

- Repeatable Accuracy: 10um

- Max. Rapid Speed X + Y: 20m/min

- Max. Cutting Speed: Depended on Material

- Digital CNC Controller 4 Axis: 4th Axis Support

- Operating System with Software for Windows / Linux: √

- Supported CAM: Solidworks CAM, 2L PRO Engraving Software